KVM Vertical Mills

FEATURES

- Fit-for-purpose pulverizing mechanism

- The evenly spaced three pulverizing rollers are each supported with a narrow gap in between to the grooves of the corresponding pulverizing table. This mechanism allows high efficiency pulverization. What is more, the spring or accumulator absorbs impacts resulting from mixed-in debris and ensures quiet operation.

- Wear resistant pulverizing section

- The pulverizing section (consisting of rollers and table liners) is manufactured using our proprietary special materials. Not much relative sliding occurs between each pulverizing roller and the inner part of the table, and their peripheral speeds are low. Consequently, material grains are smoothly caught in, thereby reducing the wear rate.

- High pulverizing efficiency and low electric power consumption rate

- Thanks to the large pulverizing area per unit time, material grains are efficiently caught in, thereby reducing the recirculation flow of classified coarse grains inside the mill and consequently reducing the power consumption per unit.

- Easy particle size adjustment

- In a coarse pulverization model, the product particle size can be easily adjusted by adjusting the opening of the classifying vanes. A fine pulverization model is provided with variable speed classifying rotors for product particle size adjustment. Both models can classify raw material grains efficiently, allowing low cost production of high quality products.

- Quick load fluctuation response

- KVM models hold a smaller volume of pulverized product than comparable mills and hence respond quickly to load fluctuations.

- Automatic operation capability

- Automatic operation available when equipped with instruments such as inlet and outlet differential pressure regulators and gas temperature controllers.

- Low vibration and noise

- The three rollers in the pulverizing section rotate silently and stably. Each roller is provided with a stopper mechanism that prevents metal-to-metal contact with the table. Thus, no-load operation can be precluded, resulting in reduced vibration and noise.

- Compact installation footprint

- Installable in considerably smaller footprints than comparable mills

- Easy maintenance

- The pulverizing rollers can be replaced by swinging around hydraulically to the outside of the mill. The table liners consists of segments, each fastened with bolts. All these structural advantages contribute to easy maintenance.

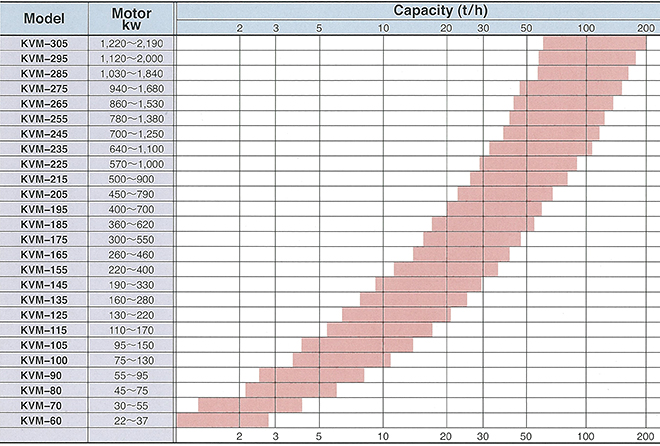

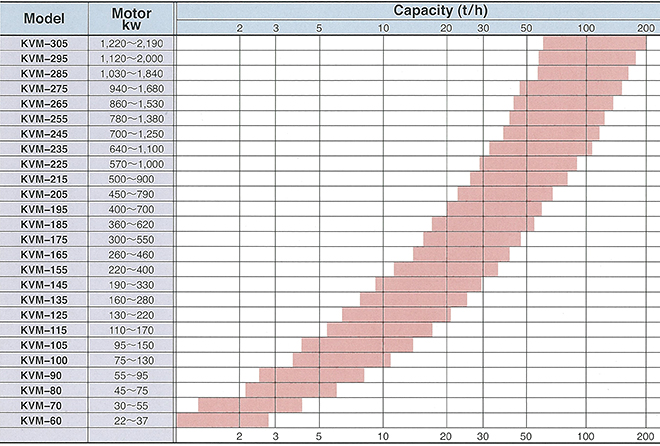

MODEL AND CAPACITY