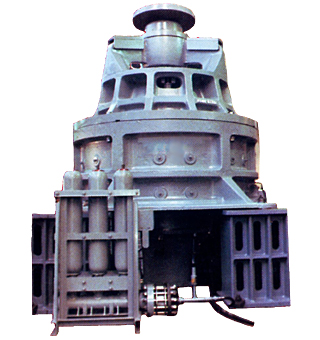

EX Cone Crusher

FEATURES

- Excellent Experience &Many Installations

- ・The first EXCONE was born in 1952.

・We have supplied more than two thousand cone crushers for the last 50 years.These EXCONE are under operation at aggrerate plants,copper and iron mines,etc,both in Japan and other locations throughout the world. - Several Kinds of Crushing Chamber

- ・Several kinds of crushing chamber are lined up for every application.

・EXCONE crusher chambers are computer designed,using a program based on many years of accumulated operating data and design experience with all kinds and types of materials. - High Strength Structure

- ・EXCONE crushers are designed with top and bottom bearing support for the mainshaft assembly.

・The same design used in all large horsepower primary gyratory crushers.Bearing loads are better distributed than in otherwise comparable machines able to take more crushing forces.

・That's one more reason why EXCONE crushers are inherently capable of doing more work than other designs.

SPECIFICATIONS

| NOMINAL SIZE |

ALLOWABLE MAX. FEED SIZE (mm) |

MOTOR OUTPUT (kW) |

ECCENTRIC THROW(mm) |

Capacity(mt/h) at Large ECC | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Close Size Setting(mm) | ||||||||||||||||||

| 3 | 5 | 6.5 | 8 | 9.5 | 11 | 13 | 16 | 19 | 22 | 25 | 32 | 38 | 45 | 50 | ||||

| 236 | 25×35×50 | 45-95 | 13-29 | 19 | 32 | 40 | 47 | 50 | 52 | 57 | 62 | |||||||

| 436 | 50×70×100 | 37-95 | 9.5-29 | 25 | 33 | 42 | 50 | 60 | 70 | 85 | 95 | |||||||

| 736 | 75×105×150 | 37-95 | 9.5-29 | 36 | 38 | 52 | 69 | 88 | 112 | 126 | 162 | |||||||

| 345 | 40×60×80 | 95-130 | 19-35 | 33 | 50 | 69 | 61 | 86 | 93 | 105 | 115 | |||||||

| 645 | 75×105×150 | 75-130 | 16-35 | 62 | 77 | 92 | 108 | 140 | 160 | 168 | 177 | |||||||

| 945 | 120×170×240 | 75-130 | 16-35 | 87 | 113 | 139 | 166 | 220 | 256 | 266 | ||||||||

| 3½51 | 50×70×100 | 60-150 | 13-35 | 34 | 62 | 65 | 94 | 103 | 112 | 125 | 145 | |||||||

| 651 | 75×105×150 | 60-150 | 13-35 | 63 | 80 | 100 | 115 | 130 | 165 | 185 | 200 | 210 | 230 | |||||

| 851 | 90×125×180 | 60-150 | 13-35 | 70 | 90 | 115 | 140 | 165 | 210 | 240 | 260 | 270 | 260 | |||||

| 1051 | 125×175×250 | 60-150 | 13-35 | 80 | 110 | 140 | 170 | 200 | 270 | 310 | 320 | |||||||

| 460 | 50×70×100 | 150-220 | 25-38 | 75 | 100 | 120 | 135 | 145 | 165 | 185 | ||||||||

| 760 | 90×125×180 | 110-220 | 19-38 | 115 | 140 | 170 | 215 | 270 | 280 | 290 | 300 | 315 | ||||||

| 1060 | 125×170×250 | 110-220 | 19-38 | 145 | 175 | 205 | 270 | 330 | 350 | 360 | 370 | 380 | ||||||

| 1260 | 150×210×300 | 110-220 | 19-38 | 180 | 210 | 240 | 315 | 410 | 425 | 440 | ||||||||

| 4½72 | 60×85×120 | 190-300 | 25-45 | 110 | 140 | 170 | 210 | 220 | 240 | 260 | ||||||||

| 872 | 110×150×220 | 150-300 | 19-45 | 140 | 170 | 205 | 270 | 335 | 400 | 410 | 420 | 430 | ||||||

| 1172 | 140×200×280 | 150-300 | 19-45 | 175 | 215 | 260 | 330 | 410 | 425 | 520 | 530 | 545 | ||||||

| 1472 | 190×270×380 | 150-300 | 19-45 | 240 | 280 | 320 | 410 | 520 | 640 | 650 | ||||||||

| 584 | 70×100×140 | 190-370 | 19-50 | 215 | 265 | 320 | 380 | 435 | 460 | 505 | 530 | 555 | ||||||

| 1084 | 125×175×250 | 190-370 | 19-50 | 265 | 290 | 295 | 365 | 460 | 565 | 665 | 740 | 840 | ||||||

| 1384 | 165×230×330 | 220-340 | 25-45 | 355 | 450 | 485 | 640 | 815 | 920 | 1000 | ||||||||

| 1784 | 210×300×420 | 190-370 | 19-50 | 270 | 305 | 400 | 575 | 760 | 995 | 1185 | ||||||||

NOTE)

1.Capacity shown is based on continuous feed of typical sand stone or similar with a bulk density of 1.6 metric ton per cubic meter, minimum clay and moisture and no fine particle smaller than closed side setteing.

2.Actual capacity may vary due to charactetistics and conditions of feed material(such as compressive strength,size distribution,etc.).