Crushing/Grinding

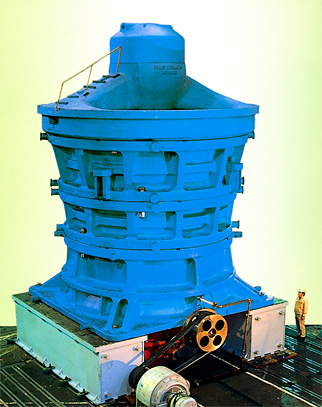

Gyratory Crusher (GY model)

FEATURES

- Excellent Design

- ・Design is a combination of the most modern engineering techniques.

・Our newest 60-109 GY provided to Kansai Airport Project phase 2 was divided into many pieces to cut tranceportation and installation cost.

・Every part built for long life. - Long Experience & Many Installations

- ・With more than 80 years experience, we have supplied more than 120 GYRATORY CRUSHERS in mines and quarries worldwide.

MOVIE

MODEL AND CAPACITY

PRIMARY CRUSHER

| Nominal Size |

Feed Opening (Mantle Dia,MAX) (mm) |

MAX. FEED SIZE (Grizzly opening) (mm) |

Pinion speed (rpm) |

Gyration (rpm) |

Eccentric Throw (mm) |

Capacity(mt/h) | Motor | Mass (t) |

||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Discharge setting(O.S.S. mm) | Power (kW) | Pole (P) |

||||||||||||||||||||

| 65 | 75 | 90 | 100 | 115 | 125 | 140 | 150 | 165 | 180 | 190 | 200 | 215 | 230 | |||||||||

| 30-55 | 760 × 2000 (1400) | 500× 700× 1000 (500) | 585 | 175 | 16 | 270 | 320 | 360 | 420 | 460 | 520 | 570 | 110 | 6 | 77.2 | |||||||

| 19 | (360) | 430 | 490 | 560 | 630 | 700 | 780 | 150 | 6 | |||||||||||||

| 25 | (460) | (560) | 630 | 710 | 800 | 880 | 990 | 190 | 8 | |||||||||||||

| 32 | (530) | (640) | (730) | 830 | 920 | 1020 | 1150 | 220 | 8 | |||||||||||||

| 36-55 | 910 × 2300 (1400) | 600× 800× 1200 (600) | 585 | 175 | 19 | 520 | 590 | 660 | 740 | 150 | 6 | 81.3 | ||||||||||

| 25 | (660) | 760 | 840 | 940 | 190 | 8 | ||||||||||||||||

| 32 | (760) | (870) | 970 | 1080 | 220 | 8 | ||||||||||||||||

| 42-65 | 1070 × 2750 (1650) | 700× 950× 1400 (700) | 497 | 150 | 25 | 830 | 940 | 1050 | 1160 | 1360 | 1540 | 220 | 8 | 117.0 | ||||||||

| 32 | (970) | 1110 | 1230 | 1370 | 1600 | 1820 | 260 | 8 | ||||||||||||||

| 38 | (1120) | (1270) | (1430) | 1580 | 1850 | 2100 | 300 | 8 | ||||||||||||||

| 48-74 | 1220 × 3050 (1880) | 800× 1100× 1600 (800) | 497 | 135 | 25 | 1290 | 1400 | 1510 | 1620 | 1740 | 1890 | 2040 | 220 | 8 | 227.0 | |||||||

| 32 | (1750) | 1900 | 2060 | 2210 | 2370 | 2580 | 2790 | 300 | 8 | |||||||||||||

| 35 | (1990) | (2160) | 2320 | 2510 | 2690 | 2930 | 3150 | 340 | 8 | |||||||||||||

| 41 | (2160) | (2350) | (2530) | 2730 | 2930 | 3180 | 3430 | 370 | 8 | |||||||||||||

| 54-74 | 1370 × 3350 (1880) | 900× 1200× 1800 (900) | 497 | 135 | 25 | 1360 | 1470 | 1600 | 1690 | 1820 | 1920 | 220 | 8 | 231.0 | ||||||||

| 32 | (1850) | 2020 | 2170 | 2310 | 2480 | 2620 | 300 | 8 | ||||||||||||||

| 35 | (2100) | (2280) | 2460 | 2620 | 2880 | 2970 | 340 | 8 | ||||||||||||||

| 41 | (2280) | (2480) | (2670) | 2860 | 3050 | 3230 | 370 | 8 | ||||||||||||||

| 60-89 | 1520 × 3700 (2260) | 1000× 1350× 2000 (1000) | 497 | 125 | 25 | 1830 | 1960 | 2090 | 2270 | 2390 | 2520 | 2650 | 260 | 8 | 398.6 | |||||||

| 32 | (2110) | 2250 | 2410 | 2620 | 2760 | 2900 | 3050 | 300 | 8 | |||||||||||||

| 35 | (2410) | (2560) | 2730 | 2970 | 3140 | 3290 | 3460 | 340 | 8 | |||||||||||||

| 38 | (2620) | (2790) | (2970) | 3230 | 3400 | 3580 | 3770 | 370 | 8 | |||||||||||||

| 45 | (3180) | (3390) | (3610) | (3930) | 4140 | 4350 | 4580 | 450 | 8 | |||||||||||||

| 60-109 | 1520 × 3800 (2790) | 1000× 1350× 2000 (1000) | 435 | 110 | Discharge setting(O.S.S. mm)→ | 180 | 190 | 200 | 215 | 230 | 240 | 255 | 265 | 280 | 290 | 305 | ||||||

| 25 | 2240 | 2370 | 2490 | 2690 | 2900 | 3090 | 3290 | 3490 | 3700 | 3920 | 4140 | 370 | 12/14 | 585.0 | ||||||||

| 32 | (2700) | 2900 | 3050 | 3280 | 3510 | 3770 | 4000 | 4260 | 4490 | 4760 | 5040 | 470 | 12/14 | |||||||||

| 38 | (3300) | (3570) | 3780 | 4070 | 4380 | 4690 | 4980 | 5290 | 5600 | 5940 | 6270 | 560 | 12/14 | |||||||||

| 44 | (3920) | (4200) | (4410) | 4730 | 5080 | 5430 | 5800 | 6150 | 6500 | 6890 | 7280 | 650 | 12/14 | |||||||||

| 51 | (4560) | (4900) | (5120) | 5460 | 5870 | 6270 | 6680 | 7080 | 7490 | 7940 | 8400 | 750 | 12/14 | |||||||||

SECONDARY CRUSHER

| Nominal Size |

Feed Opening (Mantle Dia,MAX) (mm) |

MAX. FEED SIZE (Grizzly opening) (mm) |

Pinion speed (rpm) |

Gyration (rpm) |

Eccentric Throw (mm) |

Capacity(mt/h) | Motor | Mass (t) |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Discharge setting(O.S.S. mm) | Power (kW) | Pole (P) |

|||||||||||||||

| 38 | 50 | 65 | 75 | 90 | 100 | 115 | 124 | 140 | |||||||||

| 16-50 | 400 × 1400 (1270) | 270× 360× 540 (270) | 764 | 225 | 19 | 280 | 320 | 350 | 390 | 95 | 6 | 34.0 | |||||

| 25 | (320) | 360 | 410 | 450 | 110 | 6 | |||||||||||

| 32 | (450) | (500) | 550 | 620 | 150 | 6 | |||||||||||

| 24-60 | 610 × 1680 (1520) | 400× 550× 800 (400) | 585 | 175 | 19 | 320 | 360 | 410 | 450 | 490 | 550 | 130 | 6 | 73.9 | |||

| 25 | 530 | 590 | 660 | 730 | 800 | 190 | 8 | ||||||||||

| 32 | (620) | 690 | 760 | 840 | 920 | 220 | 8 | ||||||||||

| 30-70 | 760 × 2130 (1780) | 500× 740× 1000 (500) | 479 | 150 | 19 | 380 | 450 | 520 | 590 | 690 | 780 | 850 | 950 | 150 | 6 | 108.5 | |

| 25 | 660 | 760 | 870 | 1010 | 1130 | 1250 | 1400 | 220 | 8 | ||||||||

| 32 | (770) | 880 | 1020 | 1190 | 1340 | 1480 | 1650 | 260 | 8 | ||||||||

| 38 | (900) | (1020) | 1180 | 1370 | 1550 | 1710 | 1900 | 300 | 8 | ||||||||

- Note1. Capacities shown are based on an assumed feed size distribution which 100% of feed passes 90% of feed opening and 80% of feed passes 42% of feed opening.

- Note2. Capacities shown are based on continuous feed of typical limestone or similar with a bulk density of 1.6 metric ton per cubic meter, minimum clay and moisture.

- Note3. Actual capacity may vary due to charactetistics and conditions of feed material(such as compressive strength, size distribution, etc.).

- Note4. For operation in parentheses condition, please consult EARTHTECHNICA.